Railings and ironwork

Cast iron may be found in many parts of older tenements, from drainpipes and gutters, skylights or air vents, through to structural columns.

During the Second World War, people were urged to give up their ironwork for the war effort. Sadly, all those lovely iron railings were no use for building tanks and were, it is reported, dumped at sea. But where there are railings or ironwork left, it's because they were needed for safety. So, if you’ve got original cast ironwork, you know it needs to be kept maintained.

Wrought iron or cast iron?

Wrought iron is a relatively soft metal. When heated, it becomes soft and can be easily hammered into shape. Wrought iron has good tensile strength and is relatively resistant to rust, although, if is not protected or maintained, it can eventually rust.

Cast iron has been melted, poured into a mould, and allowed to harden. Designs can be very ornate and sections of work are generally held together with bolts or interlocking lugs. Cast iron can be very brittle, and is likely to break rather than bend, often without warning.

Cast iron cannot be mended with techniques used to make and mend wrought iron.

Typical problems with cast iron

You need to look out for:

- rust

- missing pieces

- cracks

- general shakiness

- damage to coping stones or where the cast iron is fixed to the wall

When checking your ironwork, be sure to look underneath and behind (a mirror may be useful).

Dealing with rust

Rust is generally caused by water getting to bare iron. As iron rusts, it expands and this can break any stonework into which the iron is inserted, and put other sections of iron under stress. Cast iron may break, and wrought iron may distort, under this stress.

Keeping iron well-painted can prevent much rust. Look out for:

- water traps around joints, flaws, areas where paint has flaked or become damaged, areas of dirt build up and plant growth

- 'pitting' or blistering on painted ironwork - a sign that the iron may be corroding beneath the paint

- rust-coloured staining on stone

- oily residue on painted ironwork, where oil-based paint may be breaking down

- places that are easily missed during painting (undersides and parts close to walls)

Rust may also be caused by a reaction between iron and other metals. This is important to remember when it comes to fixing broken ironwork.

Treating rust

Remove any corrosion from the ironwork as soon as you spot it, protecting stone from damage as you go. Spot painting is suitable for small areas. Prepare properly, as below, and sand the edges smooth before painting.

Painting of ironwork is best undertaken in spring and summer, when the weather is warm and dry. Avoid windy days, which can blow dust and debris onto fresh paint.

Painting will last longer if you:

- prepare properly

- use correct, compatible paints

- apply several thin coats rather than one thick one

Paint preparation

- remove rust and loose or damaged paint with sandpaper, wire brushes, or chisels

- sound paint can be left

- older paint may contain lead, so take precautions, using a mask and gloves, washing clothes, and showering after working

- fill small holes to prevent them becoming water traps

- reseal defective joints with oil putty

- sand existing paint to provide a 'key' for new paint

- clean all the paintwork to remove dirt and grease

- refer to paint tins, or contact manufacturers, to check your paint is compatible with existing

Repainting

Use brushes for larger and flat areas. A painting glove can be used for railings. Make sure the iron is dry before you start painting (gentle use of a blow torch or hot air gun may be useful). Apply:

- two coats of a zinc-based primer

- one coat of micaceous iron oxide

- two coats of gloss paint

Allow each coat to dry thoroughly, so all the solvents evaporate before applying the next coat.

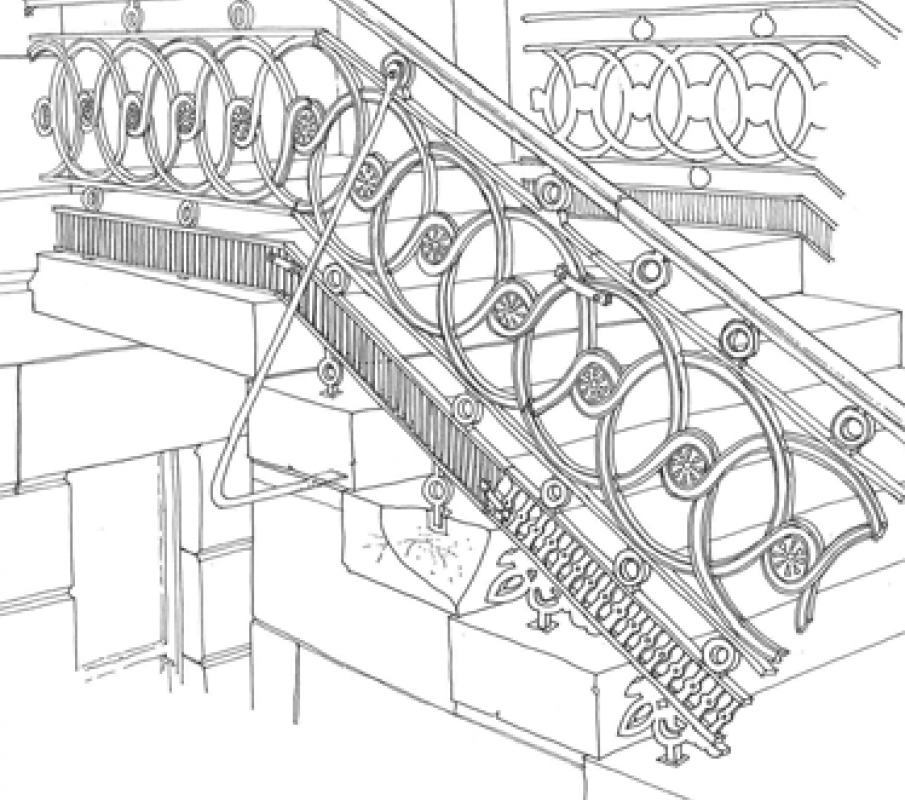

Decorative panel railings

The Victorians improved on the practice of making cast iron architectural features and these often remain as protection around basements, balconies, and on stairs.

The weak points in these cast iron panels occur where panels are linked together. Problems can arise especially where panels meet at an angle, such as at the top of stairs where they meet a landing.

Best practice was to use a wedge-shaped piece. However, short cuts were often taken, with the panels cut and butt-jointed, sometimes with a metal tie inserted at the joint of the two handrails to secure them together. This can mean that the strength lies in the welding made to join the panels, a typical weak point. In some cases, an additional metal tie can be inserted at the joint of the two handrails to secure them together.

Typically, these railings were often low enough to tempt people to sit on them. This adds stress and can lead to breaks. If panels are raised in height to prevent this happening, and to meet current building regulations, additional bow stays are required to reduce the damaging effect of this sideways force.

Breaks, impact damage, and missing pieces

Breaks

Movements of surrounding masonry, changing ground conditions, growth of tree roots, and impact all exert force on ironwork, causing cast iron to break and wrought iron to distort. A lack of bracing can also lead to breaks and damage.

Cast iron can be difficult to fix and welding repairs don't always last. Cast iron welding should only be carried out off-site and by experienced craftspeople as the use of inappropriate materials and methods can lead to more damage.

Fractures can sometimes be repaired using screws, plates, or dowels (pins). Galvanised fixings shouldn't be used as they speed up corrosion when in contact with iron. Stainless steel fixings are generally best.

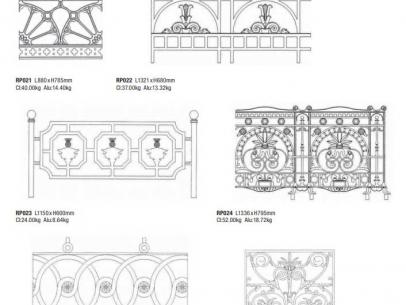

Obtaining replacements

Replacing railings or stair balusters may be less expensive than you think. Where identical moulds exist, the cost for a single railing or baluster is likely to be around £50, depending on the pattern. In about one third of cases, a new mould will need to be made using an existing piece. This could cost an additional £75 or so. A replacement panel could cost £200-£500 depending on the size.

These costs do not include the cost of using a skilled craftsperson to put the new piece in place.

Grey iron generally produces sharper detailing than spheroidal graphite, which is more resistant to impact damage. Castings should be checked for sharpness, blowholes, and other imperfections and jointing mismatches. For larger jobs, it is quite acceptable to ask for an initial sample to approve before any further castings are made.

New ironwork should be painted before reinstatement.

Cast aluminium, steel, fibreglass, and plastic are unsuitable as they have shorter lifespans and may react with iron.

Scottish suppliers

- Archibald Young

- Arthur Mcluckie

- Ballantines (who have many of the original moulds made by Walter Macfarlane)

- Charles Laing & Sons

Fixing replacements

Railings and balusters are fixed into sockets in the stone using molten lead. Stubs or broken rails can be removed or new pieces inserted between the original fixings.

Galvanised fixings can rapidly corrode and shouldn't be used. Stainless steel fixings such as pins, joints, and screws are generally best.

Cope rails may be used to add strength and height to iron panel railings, but shouldn't be welded on. Lead or pins should be used instead. Where existing cope rails are cracked or broken, they may be remade with mild steel that is bolted into the wall and carried down the stairs with fixings to all the panels. The steel cope rail will, however, be vulnerable to rust.

Wrought iron repairs

Wrought iron is no longer made and is only available as recycled material. Mild steel is sometimes used as an alternative but has a shorter lifespan, so is less economical in the long run.

Structural ironwork

Some buildings have iron support columns, which may double up as drains or iron canopies. These are especially important to keep well maintained. Where repairs are required, you must get specialist engineering and conservation advice. The conservation officer at your local council's planning department or heritage trust, or Historic Environment's Engine Shed should be able to offer helpful advice.

Steel railings

If your building was built after the 1920s, the railings will probably be steel and require regular painting.

The most modern railings are made of steel which has been galvanized before installation. However, the galvanizing may be damaged by on-site welding and the welded areas will require extra protective painting.

Listed buildings and conservation areas

If your building is listed or in a conservation area, check with your planning department as you are likely to need consent for works, including changing paint colours.

Common or individual repairs?

Unless your title deeds say otherwise, repairs to railings are generally a common repair, unless the railings are to front gardens of main door flats, when they may be an individual repair. See also close and stairs.

Further reading