Lintels

A lintel supports the walls and floors above an opening, such as a window or a door. They are part of the structure of your building. The outer lintel is made of stone or concrete. The inner lintel was often made of timber. The ends of lintels can rot if the walls they sit on are damp. These are normally common repairs.

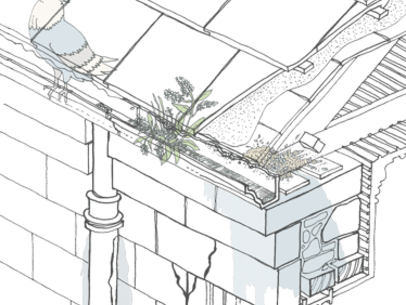

There are normally two lintels together - one supporting the inner part of the wall and the other supporting the outer wall. The inner lintel is made of timber in older buildings. The ends of timber lintels are very prone to rot if the wall gets wet - perhaps through gutters overflowing.

Problems

If the walls get wet, the internal timber lintels can rot and fail. Apart from cracks in cornices, the problem may not show outwardly until rot bursts through the linings. When the internal lintel fails, the whole weight of the wall is transferred to the outer lintel which then cracks under the pressure. Cracks in lintels can also lead to water penetration which can then lead to rot in internal timber lintels.

Iron fixings were often used to tie copings and lintels together in bay and oriel windows. Damp in the walls causes the iron to rust and expand, causing cracking near the joints.

Cracking in the padstone, which supports the lintel, is often found at bays and oriels as the lintel may be poorly seated on the padstone, stressing one small area and causing it to crack.

Solutions

- take structural engineers' advice after obtaining a survey and report

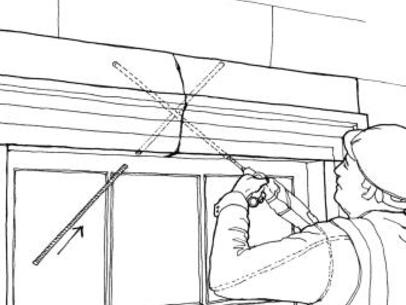

- remove the cause of dampness immediately, then replace internal timber lintels with steel or concrete lintels

- ideally, replace outer lintels with new stone lintels

- cheaper solutions include insert stainless steel staples, "stitching", or inserting stainless or galvanised steel angle under the lintel

- rusting metal fixings can often be left in place, if the rust is removed and metal treated - the stone will need to be cut back to achieve this

Professional help recommended?

You should always seek professional advice if your building needs this kind of work.

Who pays?

Lintel repairs are normally common repairs.

Further information